Making the Workplace SHARP

Safety is a top priority across the organization.

Extension helps small businesses with safety consultation services

Story by Leah Barbour • Photos by Kevin Hudson

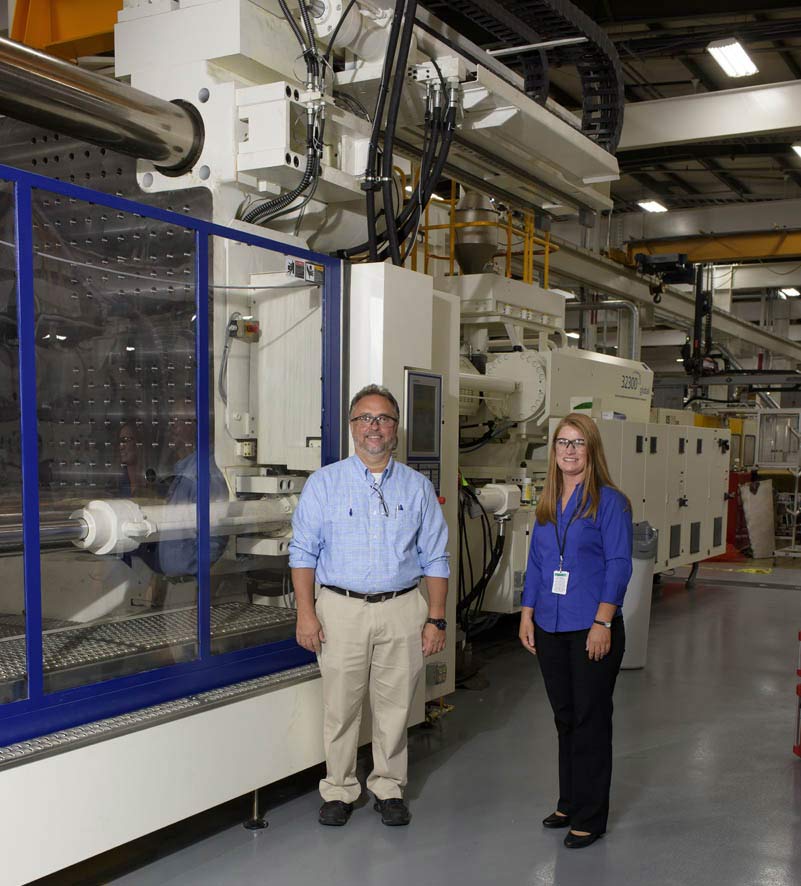

resources business partner, EcoWater Systems LLC

Small businesses in Mississippi can face workplace safety challenges with the help of a trusted partner.

A group of safety and health experts with the Mississippi State University Extension Service offers a range of free, confidential safety and health consultation services to small businesses with as many as 250 on-site employees and fewer than 500 corporate-wide employees.

Professionals with the Industrial Health and Safety Program in Extension’s Center for Continuing Education complete the same training as federal officials with the U.S. Occupational Safety and Health Administration (OSHA), but with one major difference: Extension’s purpose is educational, not regulatory, so businesses are not penalized for being out of compliance.

EcoWater Systems LLC, a residential and light-commercial water treatment system manufacturer with a large operation in Ripley in Tate County, is a longtime Extension client. Representatives at EcoWater, a Marmon/Berkshire Hathaway company, say Extension’s services have helped them enhance workplace safety culture.

Formerly known as the MSU Center for Safety and Health, Extension’s Industrial Health and Safety Program helps small businesses improve their safety in advance of federal inspections. Extension safety consultants and industrial hygienists complete walk-throughs just like OSHA officers. Then, they develop a report to advise businesses on how to make the workplace safer, such as changing or adapting the environment, providing personal protective equipment, or shifting workplace habits.

Short for Safety and Health Achievement Recognition Program, SHARP is overseen by Extension’s Industrial Health and Safety Program. The SHARP designation goes only to businesses that maintain exemplary injury and illness prevention programs. EcoWater first earned the SHARP designation in 2010, says operations manager Barney Moore, and the business has maintained it ever since.

— Barney Moore

“Our participation in SHARP has improved our safety culture,” Moore says. “These last 2 years, in our employee survey, employees rated safety a top priority across our organization. The safety culture here has changed and improved. Employees believe that management puts safety first.”

In addition to formal recognition from OSHA, businesses with SHARP designation are exempt from OSHA inspections for 2 years, barring formal complaints, imminent danger, or a fatality. Along with other benefits, SHARP businesses have lower worker compensation insurance premiums and improved worker retention.

“We look at this as a way for us to improve and make sure we are doing everything we can to keep our employees safe and healthy,” Moore emphasizes. “We’re making sure the workplace and the workers get the attention they need. Extension is helping us remain proactive, and that empowers our workforce.”

As equipment changes, the workplace changes, and those changes offer a perfect opportunity to call on trusted partners like Extension’s Victoria Bailey, a safety consultant, and Steven Holman, an industrial hygienist, Moore and Cox agree.

“Victoria, Steven, and the plant leadership have an excellent working relationship: always willing to share how we can excel, improve, and navigate through circumstances to keep our employees safe and healthy. They are always ready to help,” Cox says.

Bailey surveys various types of manufacturing, construction, and health facilities. Holman evaluates the health and hygiene of the workplace, including monitoring chemical, noise, and dust exposure.

“We only go where we’re invited to go,” Holman says, emphasizing the confidential nature of Extension’s safety services. “Small businesses contact us and request our services, but the federal government can just show up. Our opening agreement that we sign with the businesses that request our services states that our services are not disclosed to OSHA or anyone else. We cannot disclose the businesses we’ve served.”

Extension’s on-site OSHA safety consultants have helped EcoWater managers adapt at every turn as equipment and technology evolve and best practices improve, Moore emphasizes. At the end of the day, earning the SHARP designation has helped the business develop a safer work environment that enhances worker satisfaction.