Developing a Food Recall Plan

Mississippi is home to many local food and agriculture-based businesses. Because the agriculture and food sectors can be subject to a variety of disasters, natural or manmade, disaster planning and preparedness is important. The goal of the Disaster Preparedness for Food Businesses program is to help new and existing producers and processors identify and reduce potential risks associated with operating agriculture-based food businesses.

One component of risk reduction is having a recall plan in place. In the event of a recall, recall and traceability plans and actions are implemented to trace products through the supply and distribution chains and stop the spread of potentially hazardous food products in a timely manner and remove them from the marketplace. The goal of this publication is to provide information to help Mississippi producers and food business owners mitigate risks and minimize losses so they can recover after a disaster and return to normal operations.

Recall

A recall is the voluntary and/or mandatory action of removing a product from retail or distribution. Some possible events that could cause a recall include natural disasters (flood, tornado, fire), accidents, mistakes, power outages, bacterial or viral contamination, pandemic situations, and manmade disasters (intentional contamination, improper labeling, allergen mislabeling). The primary objectives in a recall event are to—

- eliminate or reduce potential deaths, illness, or injury

- effectively communicate and coordinate

- reduce economic losses

- restore consumer confidence

The U.S. Department of Agriculture (USDA) and Food and Drug Administration (FDA) have the authority to issue a mandatory recall. USDA mandates that companies have a recall plan in place. More recently, the Food Safety Modernization Act (FSMA) gave the FDA mandatory recall authority.

All establishments, including farm businesses or small processors/entities, should assess their vulnerabilities to natural and manmade disasters to assist with food defense and business survivability. Remember that recall and traceability plans ultimately help mitigate risks. Most business operations want to avoid any negative publicity associated with federally mandated actions and recalls. Businesses that are proactive generally benefit from their prompt response and communication in recall situations.

Unforeseen events or disasters can create food safety risks that could impact different aspects of the food supply chain and multiple companies. Disasters that impact agricultural and food production operations can occur on very different scales:

- Large-scale – Affects many business entities in the supply chain. Examples: ingredient contamination due to flooding, improper storage, improper handling/processing.

- Small-scale – Affects a smaller area (e.g., one county or one facility). Examples: warehouse contamination due to tornado damage, roof leak, temperature abuse.

- Variable-scale – Intentional, unknown at time, or other manmade disaster. Examples: allergen contamination, product mislabeling, foreign material (e.g., plastic, metal, chemicals) intentionally placed into product.

Recalls are divided into three classes:

- Class I – Dangerous or defective products that predictably could cause serious health problems or death. Examples: Clostridium botulinum toxin, E. coli 0157:H7 or Shiga toxin-producing E. coli (STECs), undeclared allergens, hazardous chemicals or toxic substances.

- Class II – May cause a temporary health problem or pose only a slight threat of a serious nature. Examples: spoilage microorganisms, extraneous materials, drug residues, unauthorized substances, etc.

- Class III – Products that are unlikely to cause any adverse health reaction but violate federal (USDA/FDA) labeling or manufacturing regulations. Examples: mislabeling, undeclared ingredients (non-allergenic), improper weight.

Intentional Contamination and Recall

Internal intentional contamination is a serious concern for food businesses and should be included in recall plans. The impact of intentional contamination could be large (depending on the size and scale of the operation), and the responsible individual would likely go to great lengths to conceal the sources of contamination. This type of intentional contamination and harm could be the actions of a disgruntled employee.

Intentional food product contamination usually is intended to affect a large number of people (consumers). Intentional contamination substances could be highly toxic chemicals or pathogenic microorganisms intentionally added to multiple food sources. If multiple products were contaminated simultaneously, this would add confusion and increase the impact.

Essential Components of a Recall Plan

Introduction

- Identify the business

- Background information on products and processes

- Information about scheduled reviews of the recall plan

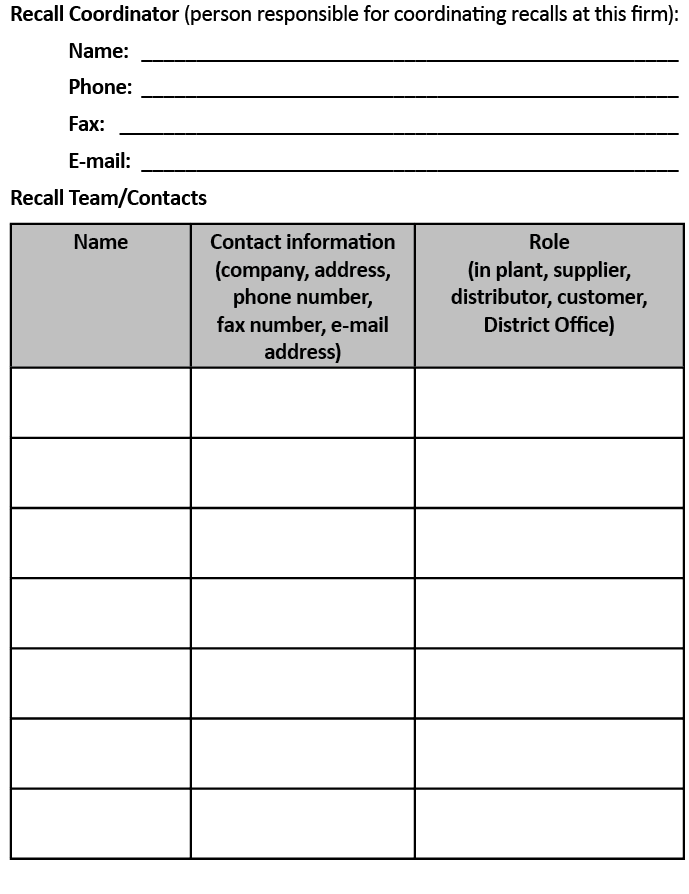

Identification of Recall Committee

- Names

- Multiple means of contact information for each member

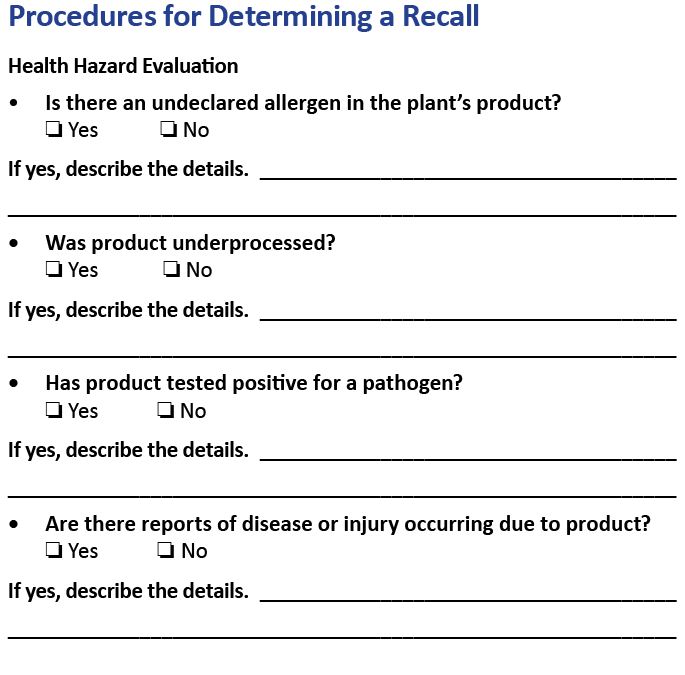

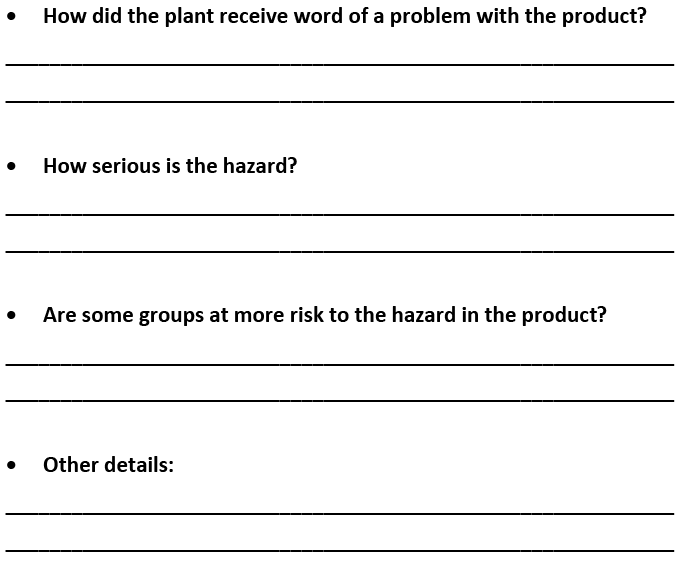

How to Determine if a Recall is Necessary

- Necessary questions and answers: what, when, where, product ID info, class of recall, packaging, other available information

Scope of Recall

- Specifics of what, where, how much of the product in marketplace, remaining inventory

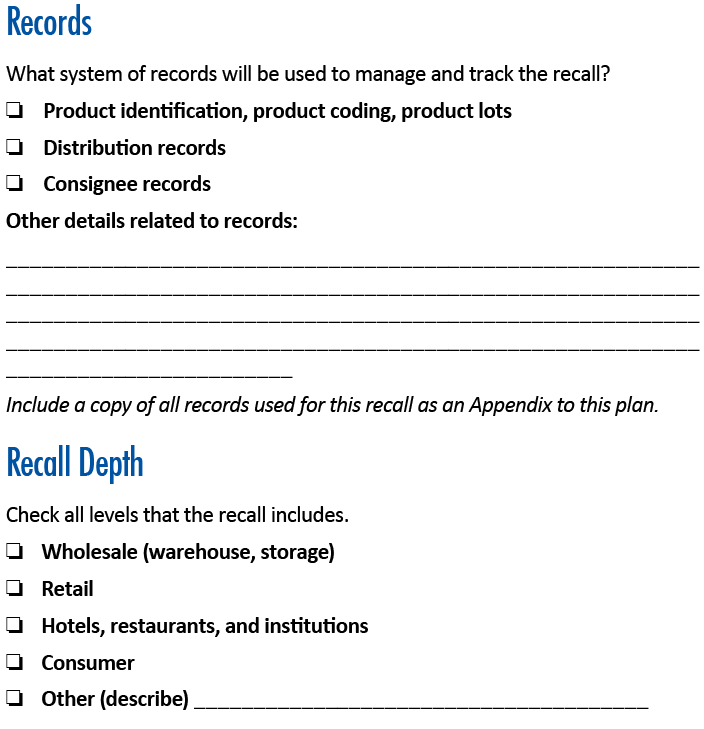

Records

- Production, maintenance, product identification, distribution/shipping records, sanitation

Depth of Recall

- Level of the supply chain where recall needs to occur: retail, wholesale, consumer, food service, all levels

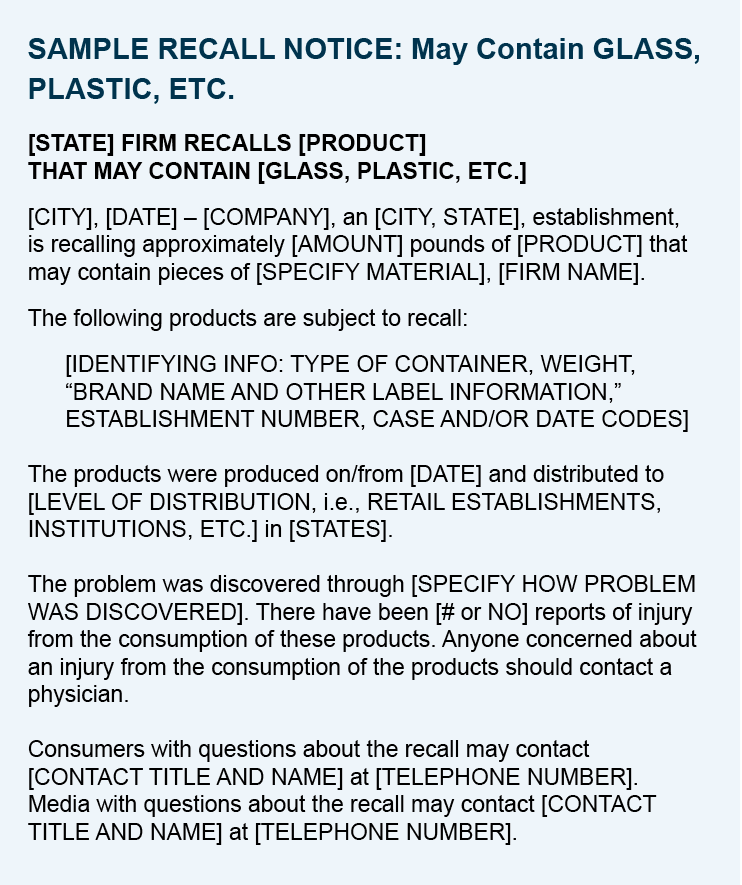

Recall Communications

- Basic guidelines and specifics to include: name, brand, lot, code, risk level, reason, means of communication, company contact info

Responsibility of Recipient

- What customers should do upon recall notification

Public Notification

- If significant recall is warranted, may need to extend to public and mass public announcement

Effectiveness Checks

- Contact all consignees; direct contact to customers via phone, email, letter, personal visit, text, and document

- Coordinate mock recalls periodically but at least annually

Records

- Keep for all communications

Product Return Logistics and Disposition

- Means for product return, holding, disposition; use very secure means (separate location from operations if possible)

Steps to Develop a Recall Plan

- Select a recall coordinator. This person should—

- prepare for and coordinate all activities related to recalls.

- be knowledgeable about every aspect of the firm’s operations.

- be authorized to make decisions in carrying out a recall.

- Build a recall team. This team should include personnel from all parts of the business (sales, production, shipping, technical, top management, public relations/HR, legal counsel, consumer representative, maintenance).

- Determine the methods for traceability, both forward (customers of your products) and backward (suppliers of raw materials) from your operation, and write procedures necessary to locate products from either direction.

- Pre-write all necessary forms/announcements for the media, customers, regulatory agencies. For guidance, see MSU Extension Publication 3498 Preparing to Respond: Four Steps to Developing a Crisis Communication Plan.

- Contact a third-party expert or process authority who can evaluate your recall plan for completeness and effectiveness.

- Fully conduct periodic mock recalls and modify your plan based on areas needing improvement.

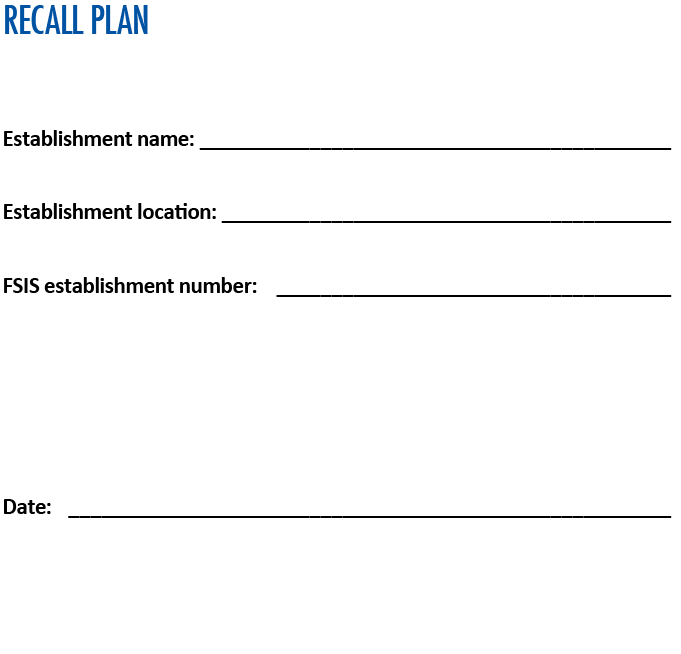

Appendix: Recall Documents and Recall Letter Examples

Source: United States Department of Agriculture – Food Safety and Inspection Service (USDA-FSIS). How to Develop a Meat and Poultry Product Recall Plan. https://www.fsis.usda.gov/shared/PDF/RecallPlanBooklet_0513.pdf

References and Resources

Conference for Food Protection. Emergency Action Plan for Retail Food Establishments, Second Edition

Food and Drug Administration (FDA). 21 CFR 7, Subpart C (Voluntary Recall Guidelines). April 2019

Food and Drug Administration (FDA). Protect Food and Water During Hurricanes and Other Storms

Food and Drug Administration (FDA). Food Defense and Emergency Response for Retail Food

Institute of Food Technologists (IFT). Global Food Traceability Center

MSU Extension Service Publications

P3497 Disaster Preparedness for Food Businesses: An Overview

P3498 Preparing to Respond: Four Steps to Developing a Crisis Communication Plan

This material is based upon work supported by USDA/NIFA under Award Number 2018-70027-28585.

Publication 3542 (10-23)

By J. Byron Williams, PhD, PAS, Associate Extension Professor, Food Science, Nutrition, and Health Promotion; Courtney A. Crist, PhD, Assistant Extension Professor, Food Science, Nutrition, and Health Promotion; Elizabeth Canales, Assistant Professor, Agricultural Economics; Carley C. Morrison, PhD, Assistant Professor, Human Sciences.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.