Economic Impact of Mississippi's Poultry Industry

Poultry Facts

- The poultry industry is the largest income-producing agricultural commodity in Mississippi and has been for the past 21 years.

- During the last agricultural census in 2012, Mississippi’s poultry sector exceeded $2.7 billion in sales at the farm gate.

- Total sales of poultry products by Mississippi processors in 2014 exceeded $2.87 billion.

- Mississippi produced 738 million broilers in 2014.

- Mississippi is home to Cal-Maine Foods Inc., the largest table-egg company in the United States.

- A Mississippi chicken weighs between 3.8 and 9.75 pounds when processed, depending on the market destination.

- The poultry industry in Mississippi employs more than 25,000 people across the state and generates another 46,885 jobs in supplier and ancillary industries. These include jobs in companies that supply goods and services to the poultry industry.

- The Mississippi poultry industry also contributes to the state’s economy as a whole. The broader economic impact flows throughout the entire state’s economy, generating business for firms that may initially seem unrelated to the chicken industry. Individuals working in industries as varied as banking, real estate, accounting, and printing depend on the poultry industry for their livelihood.

- In addition to job creation, the poultry industry also generates sizable tax revenues. In Mississippi, the industry and its employees paid over $912 million in federal taxes and $481 million in state and local taxes in 2016.

- In 2016, the poultry industry was responsible for as much as $18.36 billion in total economic activity throughout the state, creating or supporting as many as 72,153 total jobs.

- Mississippi ranked number 5 in the nation in broiler production in 2016.

Overview of the Industry

Food-away-from-home’s share of total food expenditures rose to 50.1 percent in 2014, surpassing at-home food sales for the first time. The U.S. poultry industry is a major supplier of protein in the United States and around the world, in large part because poultry competes very favorably against other meat protein sources in terms of cost of production. Initially, in terms of marketing, the poultry industry serves two distinctly different markets, the domestic market and the export market. The American domestic market prefers white meat, leaving much of the dark meat for export. However, the export market is constantly changing, based on conditions such as oil prices, natural disasters, wars and political conflicts, currency fluctuations, and global issues that are beyond the control of U.S. poultry companies.

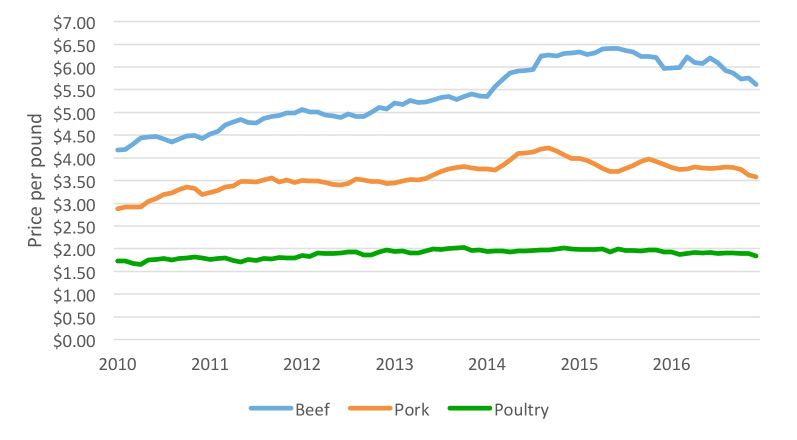

Chicken products are further divided or separated into chicken consumed at home and chicken marketed for consumption in restaurants, schools, and other institutions. Most of the white meat destined for the domestic market is further processed to increase its convenience and market value. Poultry integrators must provide products specifically processed for each market segment and to meet individual customer specifications. In the domestic market, prices are largely a function of input prices (feed being the largest input price), other competing meat prices, and the status of the U.S. economy. Poultry does very well against competing meat prices and remains a good value for the consumer. Figure 1 shows the relationship between the average retail prices paid for beef, pork, and poultry products since 2010. Poultry retail prices have remained relatively stable, while beef and pork prices have increased.

In the United States, per-capita consumption of broiler products continues to increase its lead over beef and pork, its two main competing meats. In 2015, the per-capita consumption of total broiler products reached 88.9 pounds. Per-capita consumption of beef, pork, and broilers in the U.S. totaled 192.5 pounds. Broilers constituted 46 percent of the top three meats consumed in the domestic market in 2015. Table 1 compares per capita consumption of broilers, beef, and pork from 2005 to 2015.

Export Markets

According to the United Nations, at some point, perhaps as early as 2050, if not earlier, it is estimated that there will be over 9 billion people to feed in the world, 1.3 times as many by 2050 as in 2010. The rapidly growing world population will be consuming two-thirds more animal protein by 2050 than it does today, according to World Livestock 2011, a study conducted by the United Nations’ Food and Agriculture Organization (FAO). Growing populations and incomes in developing countries around the world are fueling the trend toward increased consumption of animal protein. This increased consumption of animal protein worldwide is good news for U. S. and Mississippi poultry exports. Table 2 lists principal markets for U.S. broiler exports from 2007 through 2012.

|

Table 1. U.S per captia consumption of meats in pounds, 2005–2015. |

||||

|

Year |

Beef |

Pork |

Broilers |

Total |

|

2005 |

65.6 |

50.1 |

86.0 |

201.7 |

|

2006 |

65.9 |

49.5 |

86.7 |

202.1 |

|

2007 |

65.3 |

50.8 |

85.3 |

201.4 |

|

2008 |

62.5 |

49.5 |

83.5 |

195.5 |

|

2009 |

61.1 |

50.2 |

79.8 |

191.1 |

|

2010 |

59.6 |

47.8 |

82.4 |

189.8 |

|

2011 |

57.3 |

45.7 |

82.9 |

185.9 |

|

2012 |

57.3 |

45.9 |

80.4 |

183.6 |

|

2013 |

56.3 |

46.8 |

81.8 |

184.9 |

|

2014 |

54.1 |

46.4 |

83.3 |

183.8 |

|

2015 |

53.9 |

49.7 |

88.9 |

192.5 |

|

Source: NCC, accessed April 10, 2017. |

||||

|

Table 2. U.S. broiler exports by principal markets. |

||||||

|

Country |

2007 |

2008 |

2009 |

2010 |

2011 |

2012 |

|

|

Quantity (thousand metric tons) |

|||||

|

Mexico |

330 |

468 |

485 |

577 |

638 |

746 |

|

Hong Kong |

74 |

142 |

172 |

451 |

560 |

306 |

|

China |

698 |

797 |

741 |

138 |

134 |

288 |

|

Russia |

868 |

834 |

738 |

330 |

215 |

268 |

|

Canada |

161 |

164 |

157 |

167 |

175 |

204 |

|

Angola |

81 |

105 |

78 |

151 |

167 |

186 |

|

Cuba |

97 |

145 |

147 |

141 |

95 |

151 |

|

Taiwan |

61 |

67 |

77 |

106 |

104 |

143 |

|

Kazakhstan |

11 |

18 |

6 |

15 |

27 |

90 |

|

United Arab Emirates |

23 |

53 |

55 |

57 |

76 |

83 |

|

All others |

964 |

1,245 |

1,197 |

1,542 |

1,678 |

1,586 |

|

Total |

3,368 |

4,038 |

3,853 |

3,675 |

3,869 |

4,051 |

|

Source: USITC, 2014. |

||||||

History of Mississippi Poultry Industry

The history of the Mississippi poultry industry was described previously by Hood et al. (2012) but will be included here for clarity and background purposes. During the early part of the 20th century, there was great interest in various poultry breeds. Shows and exhibitions were quite popular, and birds were selected and bred to produce pure breeds that would place high in poultry exhibitions. During this time, breed purity was more important than bird performance and productivity. Poultry judges were prestigious and influential individuals. Some of the more popular breeds then are still popular with backyard chicken keepers today and include Orpingtons, Dominiques, Wyandotts, Plymouth Rocks, Rhode Island Reds, and Leghorns. There were a variety of plumage and color variations within most breeds.

The poultry industry began to mature during the late 1920s when commercial poultry operations began crossbreeding programs to improve bird productivity. Bird fanciers were appalled by the practice of crossbreeding and suggested that companies that crossed breeds were admitting they did not have the ability, or patience, to succeed in the purebred world. However, since then the practice of crossbreeding and the value of heterosis (the tendency of a crossbred individual to show qualities superior to those of both parents) has proven extremely successful and been demonstrated to be scientifically valuable beyond any doubt.

It was quite common in the 1920s through the 1940s to see Mississippi hatcheries located on or near the main streets of many towns across the state. Chicks were usually sold over the counter with few sales amounting to as many as 100 chicks. Most orders were small and ranged from 10 to 50 chicks. In the late 1920s, the State Poultry Federation served the poultry industry in Mississippi. There were about 35 county associations with more than 2,500 members and one area association. In the 1930s, the Mississippi Hatchery Association and the Mississippi Poultry Federation combined to form the Mississippi Poultry Producers’ Association (MPPA), which eventually developed into the present-day Mississippi Poultry Association (MPA).

In 1935, the USDA launched a program to better control and eventually eradicate pullorum disease (commonly called bacillary white diarrhea). The National Poultry Improvement Plan (NPIP) made significant progress during the early 1940s to control the disease. The percentage of pullorum reactors permitted in a flock was reduced from 10 percent in 1940 to less than 5 percent in 1945. Today, Mississippi is designated as a Pullorum-Clean State. The disease has been eradicated from commercial poultry flocks throughout the state.

There was considerable growth in the poultry industry in the U.S. during the years of World War II, as poultry became an increasingly important food source. However, this growth did not significantly impact the developing Mississippi poultry industry until the late 1940s and early 1950s. During this period, a trend developed toward “vertically integrated operations,” which are poultry companies that own their own pullet and breeder flocks, hatcheries, feed mills, and processing plants. There are several advantages to this type business model, including reduced costs on volume purchases, formation of a single profit point (at the sale of the bird), implementation of the latest technical information available, better record keeping, and improved processing and marketing opportunities. The model proved so successful that it is still used by the commercial poultry industry today.

By the mid-1950s, integrated poultry companies began contracting with local farmers to produce eggs and broilers. In general, the contract agreement dictated that the company provide chickens, feed, and technical assistance and advice. In turn, the farmer would provide land, housing, equipment, utilities, and labor. Mississippi’s huge commercial poultry industry still produces products under this type of contractual arrangement today.

The Mississippi State University Extension Service and the Mississippi Poultry Improvement Association conducted numerous poultry barbecue demonstrations throughout the state to promote increased poultry consumption. Mississippi State University conducted schools to teach the most advanced technology available. Approximately 150 to 300 poultry industry workers would attend the 2-day schools. Poultry companies hired men (referred to as “servicemen”) to assist farmers with whom they had production contracts. Poultry integrators today hire both women and men (known as “service technicians”) to provide guidance and technical assistance to contract growers to help them be more successful.

The poultry industry matured during the 1960s and early 1970s. For a variety of reasons, several companies ceased to operate efficiently and were purchased by other companies. The industry consolidated into fewer but larger companies. Today, six commercial broiler companies (Koch Foods, Mar-Jac Poultry LLC, Peco Foods Inc., Sanderson Farms Inc., Tyson Foods Inc., and Wayne Farms LLC) and one commercial egg company (Cal-Maine Foods Inc.) operate in Mississippi.

Poultry Integrators Operating in Mississippi

Koch Foods

Koch (pronounced “cook”) Foods was founded in 1973 by Fred Koch and later sold to Joseph Grendys. Koch Foods is still owned by Grendys today and, in October 2014, was ranked 163rd on Forbes’ list of most valuable private companies. The company is headquartered in Park Ridge, Illinois. In 2016, Koch Foods had sales of $3 billion and was the fifth largest poultry company in the United States with 13,000 employees, eight slaughter/processing plants, four further processing plants, one cooking plant, four distribution centers, seven hatcheries (14 million eggs weekly), and five feed mills (65,000 metric tons weekly). In 2001, Koch Foods purchased B. C. Rogers Poultry, which was headquartered in Morton, Mississippi.

Mar-Jac Poultry

Mar-Jac Poultry is a fully integrated poultry production company headquartered in Gainesville, Georgia. Mar-Jac Poultry was founded by brothers Marvin and Jack McKibbon in 1954 to serve a cooperative of poultry growers in northeast Georgia. Since that time, numerous changes, improvements, and expansions have taken place. The company was consolidated under its current ownership in 1984. Production has expanded from 450,000 birds per week in the 1980s to over 1 million per week in the 1990s and over 2 million per week today.

Mar-Jac Poultry includes two broiler companies: Mar-Jac Poultry Inc. covers the Georgia operations, while Mar-Jac Poultry LLC includes the Alabama and Mississippi operations. The Georgia operation employs 1,270 people and includes one slaughter/processing plant, one further processing plant, one hatchery (2.5 million eggs weekly), and one feed mill (manufacturing 9,500 metric tons weekly). Average bird weight per head processed is 4.2 pounds. In addition, Mar-Jac Poultry Inc. contracts with 35 breeder farms and 300 broiler farms. Mar-Jac Poultry LLC employs 1,700 people and includes two slaughter/processing plants, two further processing plants, two hatcheries (2.71 million eggs weekly), and two feed mills (8,700 metric tons weekly). Average bird weight per head is 4.18 pounds. In addition, Mar-Jac Poultry LLC contracts with 71 breeder farms and 138 broiler farms.

Peco Foods Inc.

John Herman Hickman founded what is now Peco Foods Inc. in 1937, when he agreed to raise about 75 White Leghorn chicks for a family member in Gordo, Alabama. Soon, he was knocking on doors and selling chickens to homemakers for Sunday dinners. He obtained incubators and hatching machines, and, in 1938, he began to vertically integrate his business. In late 1989, the Hickman family expanded into Mississippi with the addition of the Bay Springs processing plant and feed mill. Additional Mississippi live operations are located in Philadelphia and Sebastopol. Additional further processing operations are in Canton and Brooksville. Today, Peco Foods has operations in Alabama, Arkansas, and Mississippi. In 2016, Peco Foods had sales of $1.19 billion and was the eighth largest poultry company in the United States, with 5,941 employees, six slaughter/processing plants, one further processing plant, two cooking plants, six hatcheries (8.11 million eggs weekly), and six feed mills (60,370 metric tons weekly).

Sanderson Farms Inc.

Sanderson Farms Inc. is a publicly held, vertically integrated poultry company with more than $2.8 billion dollars in sales and with operations in Mississippi, Louisiana, Texas, Georgia, and North Carolina. Sanderson Farms was the third largest poultry company in the United States with a weekly production of 10.63 million chickens per week in 2016. Sanderson Farms has over 14,000 employees, more than 900 independent contract growers, 10 slaughter/processing plants, one further processing plant, nine hatcheries (13.25 million eggs weekly), and eight feed mills (104,400 metric tons weekly).

The company began as a farm-supply business in 1947, selling seed, feed, fertilizer, and other farm supplies. In 1951, D. R. Sanderson Sr., D. R. Sanderson Jr., and Joe Frank Sanderson organized a partnership named Sanderson Brothers. During the next few years, poultry production was added to the farm-supply business. Sanderson Farms Inc. was incorporated in 1955 and today is a fully integrated poultry processing company engaged in the production, processing, marketing, and distribution of fresh and frozen chicken and other prepared food items. Sanderson Farms Inc. is publicly traded on the NASDAQ stock exchange.

Tyson Foods Inc.

Tyson Foods Inc., headquartered in Springdale, Arkansas, was the largest poultry company in the United States in 2016, based on ready-to-cook average weekly volume in million pounds, with annual sales of $36.9 billion. Tyson Foods was founded in 1935 by John W. Tyson, whose family has continued to lead the business. His son, Don Tyson, guided the company for many years, and his grandson, John H. Tyson, serves as the current chairman of the board of directors. While owned and operated by the Tyson family, Tyson Foods is a publicly traded company on the New York Stock Exchange. Tyson Foods employs more than 114,000 people at 30 complexes across the country that include 32 slaughter/processing plants, 10 further processing plants, 13 cooking plants, 35 hatcheries, and 29 feed mills. In 1995, Tyson Foods purchased McCarty Farms, which was headquartered in Magee; and in 2003, purchased Choctaw Maid Farms Inc., based in Carthage. These acquisitions greatly expanded the company’s presence in Mississippi with the addition of large processing facilities located in both Forest and Carthage.

Wayne Farms LLC

Wayne Farms is a division of Continental Grain Company, founded in Belgium in 1813 and one of the largest privately held companies in the world. Wayne Farms has its roots in Allied Mills Inc., a former subsidiary of Continental Grain Company. Continental Grain acquired 51 percent of Allied Mills stock in 1965 and spun off the poultry division, which became known as Wayne Farms. Wayne Farms began with two initial locations in Albertville and Union Springs, Alabama. Allied Mills merged into Continental Grain Company in 1981. In 2000, the poultry division of Continental Grain Company was officially named Wayne Farms LLC. Over the past 35 years, the company has acquired several processing facilities, including a new plant in Laurel. The original facility in Laurel was constructed by Allied Mills in 1957 and was later acquired by Wayne Farms. In 2016, Wayne Farms employed more than 8,500 people at nine slaughter/processing plants, two cooking plants, one distribution center, 10 hatcheries, and nine feed mills (62,650 metric tons weekly). The company has operations in Mississippi, Arkansas, Alabama, Georgia, and North Carolina and contracts with 224 breeder farms and 855 broiler farms. Wayne Farms was the sixth largest poultry company in the United States in 2016, with annual sales exceeding $2.07 billion.

Egg Production in Mississippi

Cal-Maine Foods Inc. established its corporate headquarters in Hinds County, Mississippi, in 1963. At that time, the company employed about 200 people. Today, Cal-Maine Foods employs more than 3,400 people and maintains facilities in 15 states. On a normal day, the company processes about 15,690 cases of eggs each hour. Each case is 30 dozen eggs. In fiscal year 2016, the company sold approximately 1,053.6 million dozen shell eggs, or approximately 23 percent of domestic shell egg production. The success of Cal-Maine Foods starts with its founder, Fred Adams. In 1957, Adams took the first step to starting an enterprise that has become the largest supplier of eggs in the United States. Purchasing a truck, Adams delivered feed in rural areas surrounding Mississippi’s capitol city, Jackson. Later that year, Adams started his first chicken farm on leased property and, in 1958, began his first commercial layer operation in Mendenhall. In 1963, the enterprise expanded to build the world’s largest egg farm in Edwards, Mississippi. In 1969, Adams Foods Inc. merged with Dairy Fresh Products Company of California and Maine Egg Farms of Lewiston, Maine, creating Cal-Maine Foods Inc., supplying eggs from California to Maine. Cal-Maine produces white and brown cage-produced eggs, cage-free eggs, free-range eggs, organic eggs, and nutritionally enhanced eggs from the company’s layer flocks, which include 37.94 million hens. The company also produces liquid egg products in institutional or bulk packaging. The majority of their product mix is 53 percent fresh, 32 percent processed, and 10 percent foodservice.

Cal-Maine is a fully integrated producer and controls every aspect of production, processing, and distribution in its modern facilities, where the company carefully controls temperature, ventilation, lighting, and humidity. At its in-line processing and distribution plants, Cal-Maine gathers, grades, cleans, and packages the eggs mechanically, so no human hands touch them. Most of Cal-Maine’s shell eggs are marketed throughout the southwestern, southeastern, midwestern, and mid-Atlantic regions of the U.S. The company is a leader in industry consolidation. Since 1989, Cal-Maine has completed eighteen acquisitions ranging in size from 600,000 to 7.5 million layers.

Mississippi Poultry Industry Size and National Rank

Mississippi ranked fifth in the nation in 2016 based on the number of broilers produced. Table 3 lists the top 10 states in broiler production in the U.S. The poultry industry is the largest income-producing agricultural commodity in Mississippi and has been for the past 21 years. In 2014, 738 million broilers were produced in the state, and the Mississippi poultry industry value of production exceeded $2.87 billion. Typical broiler farms today have four to eight houses with 25,000 birds per house. One full-time worker can typically manage three to four houses. A flock of chickens reaches market size in 4 to 9 weeks, depending on the targeted market weight.

|

Table 3. U.S. Broiler Production, 2014 |

|||

|

State |

Number |

Pounds |

Value of |

|

Georgia |

1,324,200 |

7,547,900 |

4,808,012 |

|

Alabama |

1,061,500 |

6,050,600 |

3,854,232 |

|

Arkansas |

970,100 |

6,014,600 |

3,831,300 |

|

North Carolina |

795,200 |

6,043,500 |

3,849,710 |

|

Mississippi |

727,200 |

4,508,600 |

2,871,978 |

|

Texas |

591,800 |

3,550,800 |

2,261,860 |

|

Kentucky |

308,000 |

1,724,800 |

1,098,698 |

|

Missouri |

288,500 |

1,384,800 |

882,118 |

|

Maryland |

287,900 |

1,554,700 |

990,344 |

|

Virginia |

262,000 |

1,441,000 |

917,917 |

|

Source: USDA, NASS. Poultry - Production and Value 2015 Summary. |

|||

On average, a new broiler house today is about 50 feet wide and 500 feet long and costs around $250,000 to $300,000, depending on how it is equipped. However, some houses are as large as 66 feet wide and 600 feet long and may cost as much as $500,000, depending on equipment.

Broiler production is concentrated in central and southern Mississippi, with more than 1,400 farmers contracted with broiler integrators. The exact number is difficult to determine because farms change operators from time to time, and some contract farmers may own multiple houses/farms and hire family members or other individuals to manage groups of houses. Table 4 shows numbers of broilers produced by county in Mississippi and the concentration of production within the state.

|

Table 4. Estimated broiler production and value of poultry and eggs by county, 2012. |

||

|

County |

Broilers sold |

Value (dollars) |

|

Amite |

18,097,515 |

55,395,000 |

|

Attala |

2,794,040 |

(D) |

|

Clarke |

9,761,700 |

30,075,000 |

|

Copiah |

11,852,841 |

51,470,000 |

|

Covington |

39,518,912 |

148,050,000 |

|

Forrest |

4,726,290 |

13,959,000 |

|

Franklin |

1,482,148 |

5,911,000 |

|

Greene |

5,615,855 |

20,648,000 |

|

Itawamba |

546,000 |

1,614,000 |

|

Jasper |

29,399,387 |

91,762,000 |

|

Jefferson |

3,480,000 |

14,845,000 |

|

Jefferson Davis |

8,105,014 |

31,709,000 |

|

Jones |

53,710,761 |

201,268,000 |

|

Lamar |

5,702,845 |

17,839,000 |

|

Lawrence |

22,031,530 |

69,440,000 |

|

Leake |

71,924,316 |

275,215,000 |

|

Lincoln |

18,394,419 |

54,203,000 |

|

Marion |

20,997,567 |

84,313,000 |

|

Neshoba |

71,465,634 |

237,943,000 |

|

Newton |

26,374,080 |

89,552,000 |

|

Noxubee |

5,049,360 |

24,957,000 |

|

Perry |

4,403,574 |

14,368,000 |

|

Pike |

13,576,290 |

65,275,000 |

|

Rankin |

28,252,000 |

91,880,000 |

|

Scott |

62,600,500 |

255,369,000 |

|

Simpson |

52,363,235 |

186,901,000 |

|

Smith |

76,924,868 |

238,002,000 |

|

Walthall |

17,516,856 |

60,319,000 |

|

Wayne |

54,267,120 |

183,185,000 |

|

Winston |

14,527,446 |

56,794,000 |

|

Other |

5,718,383 |

71,787,000 |

|

Total |

761,180,486 |

2,744,048,000 |

|

Source: 2012 Census of Agriculture, Mississippi, State and County Data (D): Data withheld to avoid disclosing data for individual farms. |

||

Most broilers produced in Mississippi are processed at one of the 20 processing/further processing facilities in the state. Most broilers are no longer sold as whole birds; they are further processed to increase convenience and profitability. Fourteen processing facilities in Mississippi are capable of further processing. Further processing may mean the birds are cut up, deboned, formed, breaded, cooked, marinated, or specially packaged. Table 5 lists Mississippi poultry facilities, their locations, and the type operation at each location.

|

Table 5. Mississippi poultry facilities. |

||

|

Name |

Type |

Location |

|

Cal Maine Farms, Inc. |

EF |

Edwards |

|

Cal Maine Foods Inc |

FM |

Edwards |

|

Mar-Jac Poultry MS, LLC |

FM |

Waynesboro |

|

Peco Farms of Mississippi |

FM |

Bay Springs |

|

Peco Foods Inc |

FM |

Lake |

|

Sanderson Farms Inc |

FM |

Laurel |

|

Sanderson Farms Inc |

FM |

Gallman |

|

Sanderson Farms Inc |

FM |

Magnolia |

|

Sanderson Farms Inc. |

FM |

Collins |

|

Tyson Foods Inc |

FM |

Magee |

|

Tyson Foods Inc |

FM |

Union |

|

DG Foods LLC |

FP |

Hazlehurst |

|

Peco Foods Inc |

FP |

Canton |

|

Peco Foods Inc |

FP |

Brooksville |

|

Sanderson Farms Inc, Foods Division |

FP |

Flowood |

|

Tyson Foods Inc |

FP |

Vicksburg |

|

Mar-Jac Poultry MS, LLC |

H |

Waynesboro |

|

Sanderson Farms Inc |

H |

Collins |

|

Sanderson Farms Inc |

H |

Laurel |

|

Sanderson Farms Inc |

H |

Hazlehurst |

|

Sanderson Farms Inc |

H |

McComb |

|

Tyson Foods Inc |

H |

Magee |

|

Tyson Foods Inc |

H |

Newton |

|

Tyson Walnut Grove |

H |

Walnut Grove |

|

Wayne Farms LLC |

H & FM |

Laurel |

|

Koch Farms of Mississippi LLC |

H & FM |

Morton |

|

Peco Farms Inc |

H & FM |

Philadelphia |

|

Peco Foods Inc |

H & P |

Sebastopol |

|

Central Industries, Inc dba River Valley Animal Foods |

R |

Forest |

|

Sanderson Farms Inc |

R |

Monticello |

|

Griffin Industries LLC |

R |

Jackson |

|

Koch Foods, |

P |

Morton |

|

Peco Foods Inc |

P |

Bay Springs |

|

Peco Foods of Mississippi Inc, |

P |

Canton |

|

Southern Hens Inc |

P |

Moselle |

|

Water Valley Poultry LLC |

P |

Water Valley |

|

Mar-Jac Poultry MS, LLC |

P & FP |

Hattiesburg |

|

Sanderson Farms Inc |

P & FP |

Collins |

|

Sanderson Farms Inc |

P& FP |

Hazlehurst |

|

Sanderson Farms Inc |

P & FP |

Laurel |

|

Sanderson Farms Inc |

P & FP |

Summit |

|

Tyson Foods Inc |

P & FP |

Carthage |

|

Tyson Foods Inc |

P & FP |

Forest |

|

Wayne Farms LLC |

P& FP |

Laurel |

|

Koch Foods of Mississippi LLC |

P & FP |

Forest |

|

Key: EF Egg Farm, FM Feed Mill, H Hatchery, FP Further Processing, P Processing, R Rendering |

||

Economic Impact of the Mississippi Poultry Industry

The Mississippi poultry industry has a positive economic impact on many other businesses, both directly and indirectly. Many individuals and industries benefit from the poultry industry in Mississippi. For example, more than 1,400 small farmers contract with poultry integrators to produce pullets, breeders, and broilers in Mississippi. Mississippi row-crop farmers produce corn and soybeans, which are the major ingredients in poultry diets. Mississippi construction workers build poultry houses. Mississippi processing facilities hire thousands of workers to process broilers. Trucking and transportation companies ship poultry products both domestically and for export. Various manufacturers supply equipment, production and processing machinery, and paper and plastic packaging. Financial institutions help provide capital to farmers, businesses, and integrators.

Table 6 lists the economic impact of the poultry industry in Mississippi. Companies that produce and process chicken in Mississippi employed more than 25,000 people across the state in 2016. Wages and salaries paid to these employees totaled almost $1.6 billion. An additional 46,885 jobs in supplier and induced industries resulted in additional wages of $2.3 billion. The total direct, supplier, and induced economic impact of the poultry industry in Mississippi in 2016 was an estimated 72,153 jobs, with $3.9 billion in wages and a total of $18.36 billion in economic impact.

|

Table 6. Economic impact of Mississippi poultry industry. |

|||

|

|

Jobs |

Wages |

Economic Impact |

|

Direct Impacts |

|||

|

Chicken Production |

10,560 |

$1,070,034,300 |

$4,009,350,600 |

|

Chicken Processing |

14,708 |

$529,801,500 |

$4,475,749,600 |

|

Total |

25,268 |

$1,599,835,800 |

$8,485,100,200 |

|

Supplier Impacts |

|||

|

Agriculture |

2,505 |

$232,362,000 |

$216,706,300 |

|

Mining |

64 |

$4,126,000 |

$21,780,100 |

|

Construction |

446 |

$22,292,800 |

$76,593,100 |

|

Manufacturing |

5,210 |

$271,370,600 |

$3,478,208,500 |

|

Transportation & Communication |

3,894 |

$244,649,500 |

$898,694,700 |

|

Wholesaling |

2,319 |

$156,785,900 |

$515,023,400 |

|

Retailing |

495 |

$15,188,200 |

$42,009,100 |

|

Finance, Insurance & Real Estate |

621 |

$27,111,600 |

$135,896,000 |

|

Travel & Entertainment |

842 |

$18,043,400 |

$51,614,500 |

|

Business & Personal Services |

4,626 |

$233,726,300 |

$503,907,400 |

|

Government |

363 |

$28,167,000 |

$74,707,700 |

|

Other |

0 |

$0 |

$0 |

|

Total Supplier Impacts |

21,235 |

$1,253,823,300 |

$6,015,140,800 |

|

Induced Impacts |

|||

|

Agriculture |

165 |

$10,380,000 |

$21,909,200 |

|

Mining |

29 |

$1,810,700 |

$8,980,700 |

|

Construction |

321 |

$15,991,700 |

$56,435,000 |

|

Manufacturing |

1,228 |

$71,110,000 |

$660,134,900 |

|

Transportation & Communication |

1,357 |

$88,611,600 |

$449,416,900 |

|

Wholesaling |

726 |

$48,885,900 |

$160,915,800 |

|

Retailing |

3,372 |

$105,513,100 |

$266,254,200 |

|

Finance, Insurance & Real Estate |

2,978 |

$125,682,400 |

$962,868,600 |

|

Travel & Entertainment |

3,935 |

$86,782,800 |

$255,103,100 |

|

Business & Personal Services |

10,639 |

$467,308,800 |

$928,924,700 |

|

Government |

328 |

$24,165,300 |

$74,874,400 |

|

Other |

422 |

$6,710,800 |

$15,659,500 |

|

Total Induced Impacts |

25,500 |

$1,052,953,100 |

$3,861,477,000 |

|

Total Economic Impact |

72,153 |

$3,906,612,200 |

$18,361,718,000 |

|

Source: John Dunham & Associates. 2016 Economic Impact Study of the Poultry Industry. |

|||

MSU Serves the Poultry Industry

The MSU Department of Poultry Science offers bachelor’s and master’s of science degrees in several areas of specialization. The department also offers a doctoral program in agriculture with an emphasis in poultry science. In combination with the poultry industry, the department conducts research on issues faced by Mississippi growers and integrators. It works jointly with the Mississippi Poultry Association to regularly offer management schools and workshops to address specific problems affecting the industry and to keep poultry professionals current on the latest advances in poultry science. Extension specialists and researchers are available to assist integrators and growers with issues concerning housing, environmental management, lighting, water quality, mortality composting, litter management, and other areas.

The MSU Department of Agricultural and Biological Engineering works closely with Mississippi growers and integrators to provide engineering solutions to poultry housing and management challenges. The department is engaged in applied research and Extension projects that aim to increase grower and industry profitability, bird well-being, and production efficiency. Current research projects include comparing radiant heater and thermal insulation performance and characterizing spatial and temporal light levels in modern broiler houses. Specialists in the department are available to answer questions and regularly publish information relevant to the poultry industry.

The USDA South Central Poultry Research Laboratory works closely with Mississippi State University and provides valuable information to improve production practices. In addition, the laboratory provides useful information on environmental influences on production and has a premier program in Mycoplasma research that has the potential to save the poultry industry millions of dollars in losses related to this disease.

The MSU College of Veterinary Medicine in Starkville and the Mississippi Veterinary Research and Diagnostic Laboratory in Pearl conduct research on diseases affecting poultry flocks and provide testing and assistance to poultry professionals when problems arise.

The MSU Department of Food Science, Nutrition, and Health Promotion conducts research to assist the processing sector. They also conduct workshops on food safety and regulatory compliance that benefit the industry.

References

2016 Economic Impact Study of the Poultry Industry. John Dunham and Associates. New York, October 2016.

Hood, K., A. Myles, D. Peebles, and D. Thornton. 2012. The poultry industry and its economic impact. Mississippi State University Extension Service. Publ. No. 2719. March.

NCC. 2016. National Chicken Council. Per capita consumption of poultry and livestock, 1965 to estimated 2016, in pounds. Available at: http://www.nationalchickencouncil.org/about-the-industry/statistics/per-capita-consumption... Accessed: April 10, 2017.

USDA. 2012. National Agricultural Statistics Service. Census of Agriculture. Mississippi. State and county data.

USDA. 2016. National Agricultural Statistics Service. Poultry production and value – 2015 summary. April.

USDA. 2017. Economic Research Service. Meat price spreads. Available at: http://www.ers.usda.gov/data-products/meat-price-spreads. Accessed: April 12, 2017.

USITC. 2014. United States International Trade Commission. Poultry – industry and trade summary. Publ. ITS-010.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 3048 (POD-06-17)

By Tom Tabler, PhD, Extension Professor, and Jessica Wells, Extension Instructor, Poultry Science.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.